Construction Of N7.04bn Pipe Manufacturing Plant Begins At Polaku.

The construction of a N7.04 billion pipe manufacturing plant at Polaku Bayelsa State, the first of its type in the country, has eventually begun after long years of waiting.

The project which is expected to be completed within 12 months is promoted by AS Energies Limited to manufacture Glass Reinforced Epoxy (GRE) and Glass Reinforced Plastic (GRP) pipes.

Glass Reinforced Epoxy (GRE) and Glass Reinforced Plastic pipes are more resistant, lighter, less corrosive, and more durable than conventional carbon steel pipes in use in the extractive industries.

The plant on completion will facilitate technology transfer in pipe manufacturing technology and the development of a variety of skills among the local population.

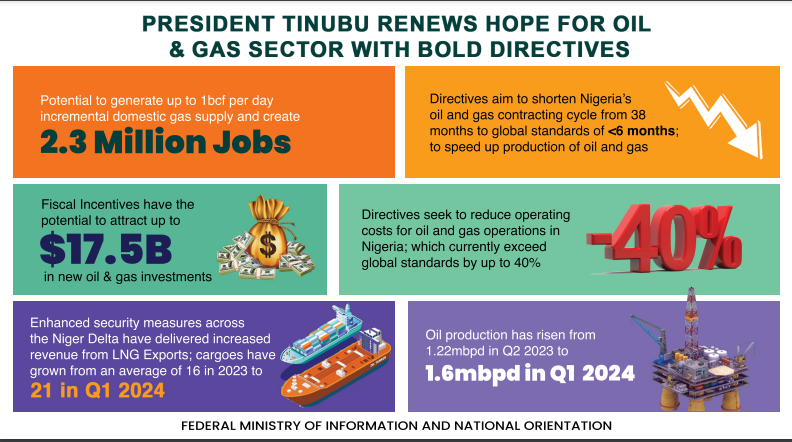

It is expected to help oil and gas to cut costs.

Simbi Kesiye Wabote, Executive Secretary, Nigerian Content Development and Monitoring Board (NCDMB) commended work on the pipe manufacturing plant, which conforms with the mission statement of NCDMB “to promote the development and utilization of in-country capacities for the industrialization of Nigeria through the effective implementation of the Nigerian Content Act’’

For a pipe manufacturing mill that had been in plans for over a decade, Wabote said the Polaku community and the Gbarain Clan, are blessed, given the concentration of strategic industries in the area, indications that others would follow.

Polaku community is a host to the Shell Gas Gathering Plant, Azikel Refinery (a modular hydro-skimming processing plant), the US$45 million Types 3 LPG Composite Cylinder Manufacturing Plant, owned by Rungas Prime Industries Limited, and Eraskon Nigeria Limited.

The Pipe Manufacturing Plant is a testament to the giant strides in local content drive in the country, and AS Energies Ltd will need the support of the NCDMB.

The NCDMB boss urged AS Energies management to produce pipes that will meet regulatory standards such as ISO 9001- Quality Management System Requirements; ISO 14001 – Environmental Management System Standard; & BS 18001 – Occupational Health & Safety Management System Standard,

Chief Executive Officer of AS Energies Ltd, Gbenga Olaniyan, said the choice of Polaku as the site for the $8.8 million project is deliberate, as the company seeks to be a development partner in the area.

Engr. Olaniyan assured that AS Manufacturing Services Ltd would integrate the community into its operational plans and activities, adding that one of its cardinal principles is to source essential materials locally in the advancement of the Federal Government’s drive for in-country value addition.

Augustine Taribene, the Managing Director, of AS Manufacturing Services Ltd, said the plant is “echo-friendly,” with a waste management policy and strategy to keep the environment free of pollution.

“We want to assure that whatever we do will not hurt the environment.”

The Ibenanaowei of Ekpetiama Kingdom, His Royal Majesty, King Bubaraye Dakolo, Agada IV, is delighted with the siting of the company in the community and thanked the NCDMB for the wonderful work it has done facilitating the establishment of major indigenous firms in the State.

The monarch urged the Management of the company to avoid the practices of international oil companies (IOCs) in the Niger Delta that have done very little to assist in the development of host communities, but have rather been engaged in divide-and-rule and causing intra- and inter-communal crises. He assured them of the full support and cooperation of the community if they take the community along in their operations.

The spokesman for the Polaku community, Kenigua Dinikpite, assured the company of the full cooperation of the indigenes’ band and expressed hope that AS Manufacturing Services Ltd would abide by NCDMB’s Community Content Guideline on obligations of corporate organisations to host communities.

Comments are closed.